How to Build a Powder Coating Oven Part II

Welcome to "How to Build a Powder Coating Oven - Part II." See How to Build a Powder Coating Oven Part 1. In part 1, we build the oven frame, we started skinning it in sheet metal, we added lights and the convection blower, and also insulation and heating elements. I am going to pick up right were we left off. This powder coating oven build was done by KNJ Custom Coating and I want to thank them for contributing all of the information and pictures.

How to Avoid Easily Chipped Powder Coat

Powder coating is usually an easy-going process that produces a brilliant and durable finish. However, occasionally; or if you're new, it may be a lot more frequent, you'll pull a part out of the oven and see that it is full of defects. The following articles will help you identify those defects and learn what you need to do to avoid seeing them again. This is the beginning of a series of articles that will help you solve issues with powder coating defects. This article will discuss one of the more serious powder coating defects: powder coat that is easily chipped.

Powder coating is usually an easy-going process that produces a brilliant and durable finish. However, occasionally; or if you're new, it may be a lot more frequent, you'll pull a part out of the oven and see that it is full of defects. The following articles will help you identify those defects and learn what you need to do to avoid seeing them again. This is the beginning of a series of articles that will help you solve issues with powder coating defects. This article will discuss one of the more serious powder coating defects: powder coat that is easily chipped. Powder Coating Guns

If you are completely new to Powder Coating, I recommend that you start off by getting a beginner powder coating gun. These are priced at less than $200. After you have that, you can try it out and see if it's something you want to pursue. This post will talk about some good powder coating guns you can start out with, but first take a look at some of the other equipment and supplies you will need:

Clicking the links will take you to the appropriate article on this site

Powder coating gun - Read about them below in this post.

- Oven

- Powder

- Something to powder coat

- Air Compressor (Unless you use the Craftsman powder coating gun)

- Non-contact Infrared Thermometer

- Grounding Rod

- Media Blaster

- Powder Coat Stripper - for WHEN you mess up.

- Degreaser & Soap

- Masking supplies: plugs, high-temp tape, blue painters tape, etc.

- Denatured Alcohol

- Disposable Gloves

- Respirator

Spraying Multiple Coats

There are several instances when powder coating where multiple coats will be involved. Often times, it is a clear coat for added protection and appearance. Sometimes it is required, chrome powders need a clear to protect them from oxidizing. Candy colors need a chrome base to achieve the candy look. Also, multiple colors can be applied onto one part to achieve a two-tone look. This article will help you apply multiple coats of powder the correct way.

There are several instances when powder coating where multiple coats will be involved. Often times, it is a clear coat for added protection and appearance. Sometimes it is required, chrome powders need a clear to protect them from oxidizing. Candy colors need a chrome base to achieve the candy look. Also, multiple colors can be applied onto one part to achieve a two-tone look. This article will help you apply multiple coats of powder the correct way.Plumbing Your Air Compressor

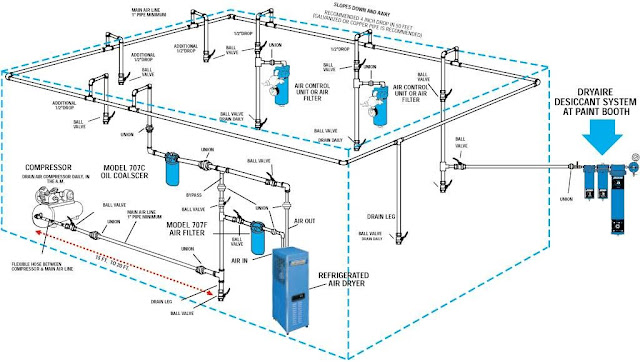

Plumbing serves a couple of purposes when it comes to your air compressor. Not only does it allow the air to get from point A to point B in your shop or garage, but it can also help to cool the air which assists in reducing moisture. This is very important for powder coating and sandblasting, as well as any other pneumatic tool you may use including HVLP paint guns and standard air tools. The material you choose for your air lines and the way it is laid out can have a drastic effect on the amount of moisture coming out at the end of your air hose as well as the CFM provided. This article will help you decide how to set up the air lines in your shop or garage.

How to Spray Powder Coat

Spraying powder coat is a fairly simple point-and-shoot job once you get the hang of it. After you have done all of the necessary cleaning, blasting, and masking; shooting the powder is the next step. This article will help you achieve the correct coating thickness and avoid orange peel and other defects.

How to Prep for Powder Coating

Powder coating requires some very specific prep work if you want your finished product to be free of flaws and last a long time. The preparation steps below will eliminate 99% of any issues you may be having in your powder coating work. If you plan to start powder coating in the future, this step-by-step will give you an idea of what kind of prep work is required for successful coating.

How to Dry Compressed Air

You have your air compressor and powder coating gun and you are ready to start powder coating? Not so fast, make sure you read this article first. When powder coating or sandblasting, you need clean, dry air. More than just compressed air comes out of the outlet of your air compressor. Water, dirt, and oil will also be included in this compressed air. It is very important that you treat your compressed air and remove these contaminants when using your air compressor for powder coating. The same information I am about to provide also applies to auto painting, compressed air machinery, or even just using common air tools. Any tool that connects to your air compressor will appreciate a clean air supply. Read this article: How to Choose an Air Compressor if you haven't purchased an air compressor yet.

You have your air compressor and powder coating gun and you are ready to start powder coating? Not so fast, make sure you read this article first. When powder coating or sandblasting, you need clean, dry air. More than just compressed air comes out of the outlet of your air compressor. Water, dirt, and oil will also be included in this compressed air. It is very important that you treat your compressed air and remove these contaminants when using your air compressor for powder coating. The same information I am about to provide also applies to auto painting, compressed air machinery, or even just using common air tools. Any tool that connects to your air compressor will appreciate a clean air supply. Read this article: How to Choose an Air Compressor if you haven't purchased an air compressor yet.

Choosing an Air Compressor

An air compressor is an essential component in nearly all powder coating applications. It provides the air necessary for media blasting, blowing off parts, and of course, a powder coating gun.

To those that are on the fence about whether they decide to get into powder coating, an air compressor may seem like an expensive item that takes up too much space. Don’t let that prohibit you though. Air compressors come in all shapes, sizes, and prices; and there is one available for every level of powder coater, from a complete beginner, to a large established shop.

An air compressor is also incredibly useful to have available to you, even when you’re not powder coating. A large world of pneumatic tools becomes available to you, with the right air compressor.

This article will cover the basic parts of an air compressor and the terminology used to describe its performance. I am hoping that this information will help you to choose the right air compressor that will assist your powder coating experience.

To those that are on the fence about whether they decide to get into powder coating, an air compressor may seem like an expensive item that takes up too much space. Don’t let that prohibit you though. Air compressors come in all shapes, sizes, and prices; and there is one available for every level of powder coater, from a complete beginner, to a large established shop.

An air compressor is also incredibly useful to have available to you, even when you’re not powder coating. A large world of pneumatic tools becomes available to you, with the right air compressor.

This article will cover the basic parts of an air compressor and the terminology used to describe its performance. I am hoping that this information will help you to choose the right air compressor that will assist your powder coating experience.

Where to Buy Powder

There are several companies that manufacture powder coating powders. Dupont, PPG, NIC, Tiger Drylac, Sherwin Williams, & 3M are some popular manufactures. However, large companies like these prefer to sell large quantities of powder. It is not practical for them to mess around with selling 1lb here and 1lb there. Some of their "sample sizes" are 50lb boxes. As a small, custom powder coater, you will probably not want 50lbs of any one color so ordering directly from these companies isn't practical. Luckily there are companies out there that buy these powders in the large quantities and re-sell them in much smaller quantities. This allows you to buy powders in 1lb quantities, and in some cases, even 1/2lb quantities. The average price for a pound of powder is about $12 and 1 pound can go a long way.

There are several companies that manufacture powder coating powders. Dupont, PPG, NIC, Tiger Drylac, Sherwin Williams, & 3M are some popular manufactures. However, large companies like these prefer to sell large quantities of powder. It is not practical for them to mess around with selling 1lb here and 1lb there. Some of their "sample sizes" are 50lb boxes. As a small, custom powder coater, you will probably not want 50lbs of any one color so ordering directly from these companies isn't practical. Luckily there are companies out there that buy these powders in the large quantities and re-sell them in much smaller quantities. This allows you to buy powders in 1lb quantities, and in some cases, even 1/2lb quantities. The average price for a pound of powder is about $12 and 1 pound can go a long way.

Subscribe to:

Posts (Atom)